Hemi For The Water: Amphibious Motorsports

- By Tyler Speer

- •

- 22 Apr, 2016

- •

On the surface all engine builders strive for the same goals — power, torque, reliability, and ease of maintenance. But where the differences come in are between each field of racers’ respective arena. Stock cars and road racers run with high lateral G-loads, desert racers have to contend with extreme vibration and heat, aircraft have to solve lubrication problems at any attitude, but those who take to the water have their own unique challenges.

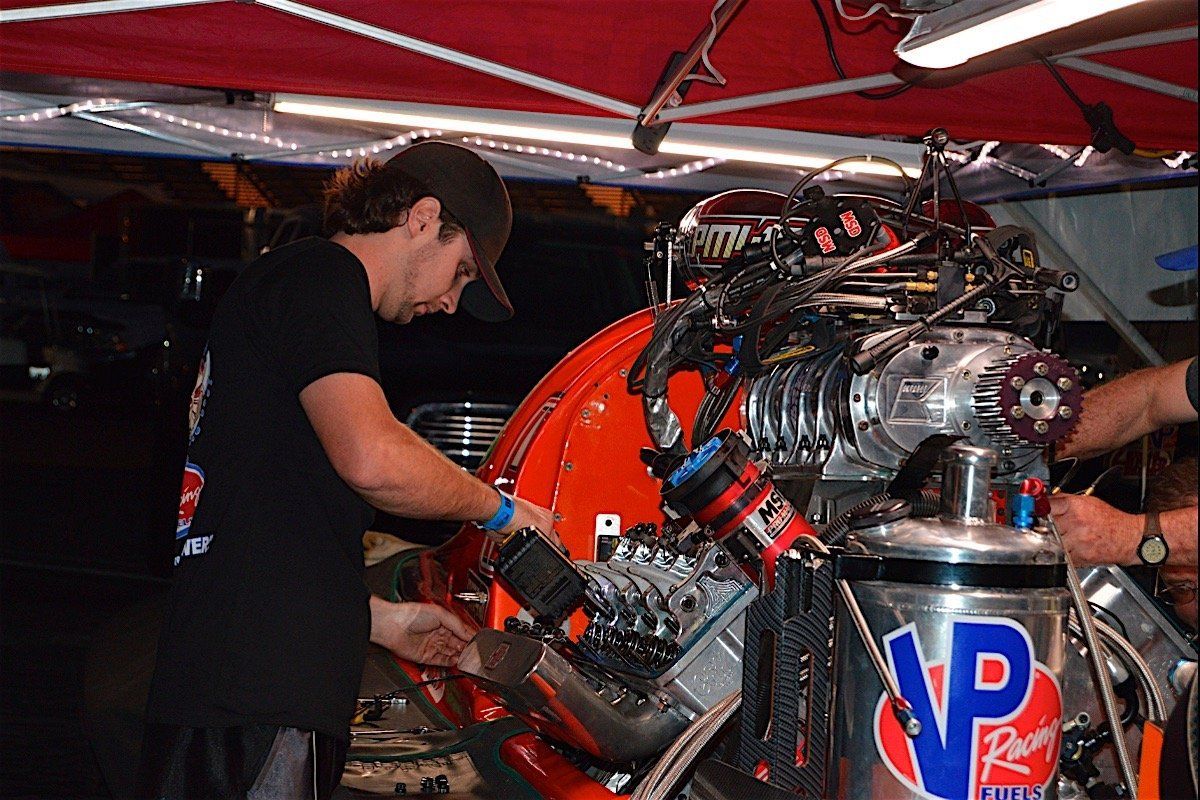

Drag racing on the water exposes engines and systems to corrosive spray, long idle times hanging onto the start rope before a run, and peculiar packaging considerations to accommodate V-drives as well as exotic induction systems. We met up with one of these H2O racers and decided to dig a little into their engine program.

Tyler Speer of Amphibious Motorsports is a fresh face to the world of drag racing on the water, but not green to the world of boats, speed, and engines.

Drag racing on the water exposes engines and systems to corrosive spray, long idle times hanging onto the start rope before a run, and peculiar packaging considerations to accommodate V-drives as well as exotic induction systems. We met up with one of these H2O racers and decided to dig a little into their engine program.

Tyler Speer of Amphibious Motorsports is a fresh face to the world of drag racing on the water, but not green to the world of boats, speed, and engines.

Originally purchasing the boat in 2014, Speer and his father brought the boat into competitive focus. With a background in building big block Chevrolet engines the family duo initially set out to continue that trend in their new hull. While mulling over the possibilities they made some contacts that offered another fork in the road to follow.

“Chris Vandergriff from Hedman Headers needed some work done on their offshore boat so I ended up building two 502s for them. Long story short I built the 502s for them and in return we got the Hemi — it came from Andy Bohl who runs a Top Alcohol Funny Car,” Speer recalled. Having never worked with Hemi platforms there were certainly some differences from the safety blanket of BBC engines. Of course many of the challenges and schools of thought are the same, other areas, such as valvetrain, pose new challenges and learning opportunities.

“When we originally got the engine in 2014 it was the first time we’d dealt with anything Hemi-related. We’ve always done BBC Chevys and there was a pretty big learning curve. We took it to be dynoed with our blower, hat, and fuel pump — the first time we put it on the dyno it made 1,800 horsepower,” Speer explained.

It’s no secret that brand-loyalties can run deep in motorsports, and the Ford versus Chevy versus Mopar debate rages on for many. For Speer the decision to change platforms was one based in logic and past experience — gathered both first hand and from observation of competing teams. “The biggest reason we wanted to go with the Hemi more than the Chevy after looking at both of them is two things, the Hemis can handle all the power you want to throw at them — we run a whole season on just a freshen-up half way, for the most part the Chevy guys are maxing everything out just trying to get everything they need to run the 7-seconds,” Speer articulated.

“Chris Vandergriff from Hedman Headers needed some work done on their offshore boat so I ended up building two 502s for them. Long story short I built the 502s for them and in return we got the Hemi — it came from Andy Bohl who runs a Top Alcohol Funny Car,” Speer recalled. Having never worked with Hemi platforms there were certainly some differences from the safety blanket of BBC engines. Of course many of the challenges and schools of thought are the same, other areas, such as valvetrain, pose new challenges and learning opportunities.

“When we originally got the engine in 2014 it was the first time we’d dealt with anything Hemi-related. We’ve always done BBC Chevys and there was a pretty big learning curve. We took it to be dynoed with our blower, hat, and fuel pump — the first time we put it on the dyno it made 1,800 horsepower,” Speer explained.

It’s no secret that brand-loyalties can run deep in motorsports, and the Ford versus Chevy versus Mopar debate rages on for many. For Speer the decision to change platforms was one based in logic and past experience — gathered both first hand and from observation of competing teams. “The biggest reason we wanted to go with the Hemi more than the Chevy after looking at both of them is two things, the Hemis can handle all the power you want to throw at them — we run a whole season on just a freshen-up half way, for the most part the Chevy guys are maxing everything out just trying to get everything they need to run the 7-seconds,” Speer articulated.

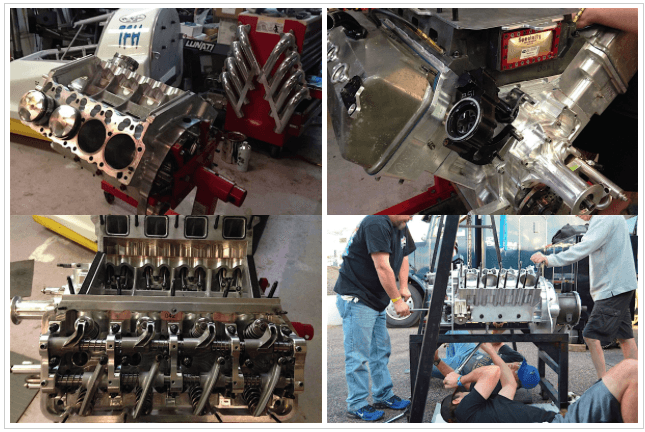

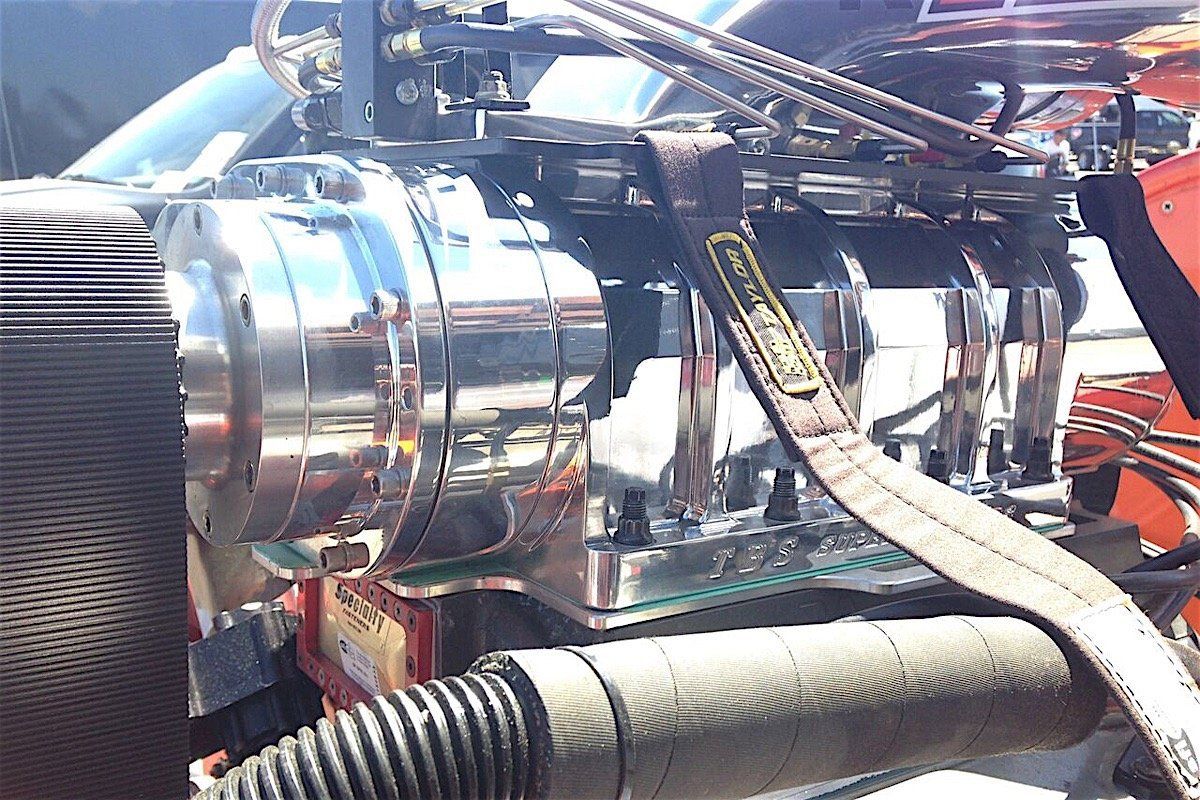

With a proven, albeit, hand-me-down engine from the dry side of the drag racing world, the Speers set in for some modifications. Tearing into the engine and building it out they opted to stick with the Funny Car bottom end and conservative compression ratio that complimented the screw-blower originally force-feeding the V8. “It’s a 505 cubic inch displacement and has the same bottom end that the alcohol Funny Cars run, it’s a 10.5:1 motor and we didn’t really change the compression ratio. We could bump it up to 11 or 12 or more if we wanted to but we’re only running 25 pounds of boost. We want to stay in the bracket so we kind of de-tuned it,” Speer illustrated.

The 2014 season was more or less an opportunity to get the Speers’ feet wet with the new Hemi. Only running one race to get licensed in 2014 they came away with a better understanding of what needed to be done power-wise to compete in the 7-second bracket. After scaring up an old Top Fuel blower and re-tuning the Hemi, a little more power was on tap, but more was needed.

In the 2015 season a minor disaster befell Amphibious Motorsports, “This past season it dropped one of the valves, the titanium retainer just came apart. We blew it up pretty good and tore the heads up — we didn’t have a spare so we went from 6th to 9th in one weekend. We came back at the world finals and ended up finishing third,” Speer lamented. In the run-up to the 2016 season the Hemi has seen a new rebirth.

The 2014 season was more or less an opportunity to get the Speers’ feet wet with the new Hemi. Only running one race to get licensed in 2014 they came away with a better understanding of what needed to be done power-wise to compete in the 7-second bracket. After scaring up an old Top Fuel blower and re-tuning the Hemi, a little more power was on tap, but more was needed.

In the 2015 season a minor disaster befell Amphibious Motorsports, “This past season it dropped one of the valves, the titanium retainer just came apart. We blew it up pretty good and tore the heads up — we didn’t have a spare so we went from 6th to 9th in one weekend. We came back at the world finals and ended up finishing third,” Speer lamented. In the run-up to the 2016 season the Hemi has seen a new rebirth.

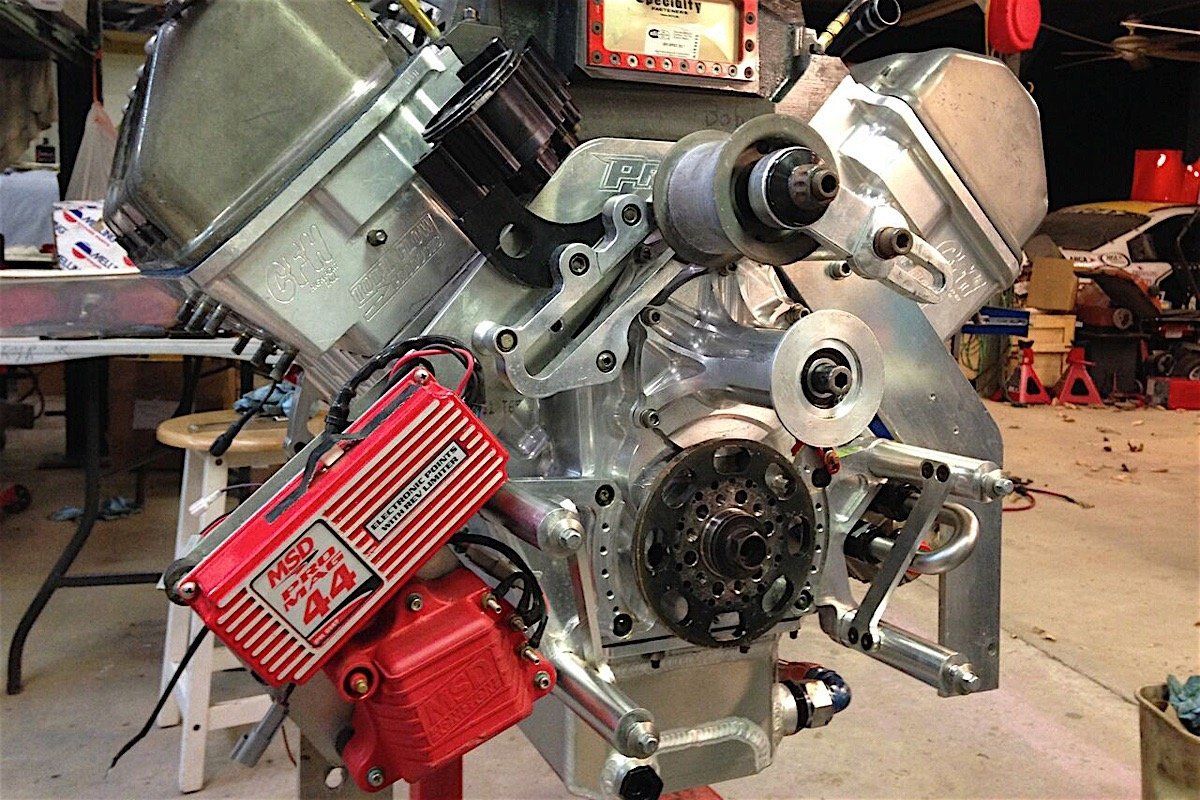

The engine is sleeved to an NHRA-legal 500-cubic inch displacement and utilizes a new TBS 1471 high-helix supercharger, Enderle fuel injection, MPG connecting rods, CP pistons, a COMP camshaft, Brad Anderson block, and Chuck Ford tall-deck cylinder heads. The valvetrain employs Manton rocker assemblies and pushrods, currently needle-bearing style lifters are used but plans are in motion to convert to bushing style to avoid the debris clean up inside the engine anytime something bad happens.

Electronics’ demands were kept to a minimum to prevent issues in the wet environment, for ignition Speer turned to an MSD Mag 44 unit. Keeping tabs on the status of things is an Autometer data-logger.

Electronics’ demands were kept to a minimum to prevent issues in the wet environment, for ignition Speer turned to an MSD Mag 44 unit. Keeping tabs on the status of things is an Autometer data-logger.

The drive configurations of a Pro-Mod boat preclude the conventional mounting of an engine, in order to route the driveline to a V-drive system the engine is flipped front to rear. With this change in packaging comes a few tricky considerations mainly affecting the induction system — providing a clear path for air to enter the supercharger becomes challenging, and the lubrication system.

“Everybody else that runs with us runs at least a 2-speed drive, were one of the only teams running a direct drive. The motor sits in the boat backwards in a Pro-Mod boat, which reeks a little havoc when you’re trying to get the airflow into the blower,” Speer concluded. “We run the ARCA series as well, so we’re running a Peterson 5.5-gallon dry sump tank. We run 4.5-gallons and its just a single stage pump. We had some oil scavenging problems when we ran the original pickup that came out of the Funny Car, so we went to Dan Olson for a reverse pan for the Hemis.”

The resulting powerplant propels Amphibious Motorsports into close contention at each Lucas Oil Drag Boat race. With plans to run Top Fuel in the near future, we hope to have a look into what conversion steps take place. In the meantime we wish Tyler Speer and his crew the best of luck at their events around the country.

Article Source: EngineLabs.com by Trevor Anderson

“Everybody else that runs with us runs at least a 2-speed drive, were one of the only teams running a direct drive. The motor sits in the boat backwards in a Pro-Mod boat, which reeks a little havoc when you’re trying to get the airflow into the blower,” Speer concluded. “We run the ARCA series as well, so we’re running a Peterson 5.5-gallon dry sump tank. We run 4.5-gallons and its just a single stage pump. We had some oil scavenging problems when we ran the original pickup that came out of the Funny Car, so we went to Dan Olson for a reverse pan for the Hemis.”

The resulting powerplant propels Amphibious Motorsports into close contention at each Lucas Oil Drag Boat race. With plans to run Top Fuel in the near future, we hope to have a look into what conversion steps take place. In the meantime we wish Tyler Speer and his crew the best of luck at their events around the country.

Article Source: EngineLabs.com by Trevor Anderson